Introduction

Industrial automation is rapidly reshaping the global manufacturing landscape. As factories adopt digital technologies, robotics, artificial intelligence (AI), and data-driven systems, production is becoming more efficient, resilient, and innovative. By 2030, these changes will not only redefine how products are made but also who makes them and the skills required to thrive in an automated future.

Industrial IoT and Smart Factories

One of the foundational shifts in manufacturing is the emergence of the Industrial Internet of Things (IIoT) – a network of connected devices and sensors that collect and share data in real time. This connectivity enables predictive maintenance, reducing unplanned downtime and extending equipment life. According to industry forecasts, IoT-driven systems can cut equipment failures by up to 70% and decrease maintenance costs by 25% – a major efficiency gain for heavy industries.

Smart factories, powered by IIoT, use real-time analytics to optimize every stage of production, enabling faster decision-making and better use of resources. Companies that adopt these technologies can reduce energy consumption and improve operational flexibility – a key competitive advantage in an uncertain global market.

Artificial Intelligence and Machine Learning

AI and machine learning are the brains behind the next generation of automation. These technologies can analyze vast amounts of data from sensors and machines, identify patterns, and make decisions without human intervention. By 2030, many factories aim to become “AI-native,” meaning their systems can self-optimize production schedules, predict failures before they occur, and automatically adjust for quality issues.

Real-world implementations already show dramatic improvements: some AI-native facilities report up to 3× productivity gains and 50% fewer defects, while reducing energy use by as much as 30%.

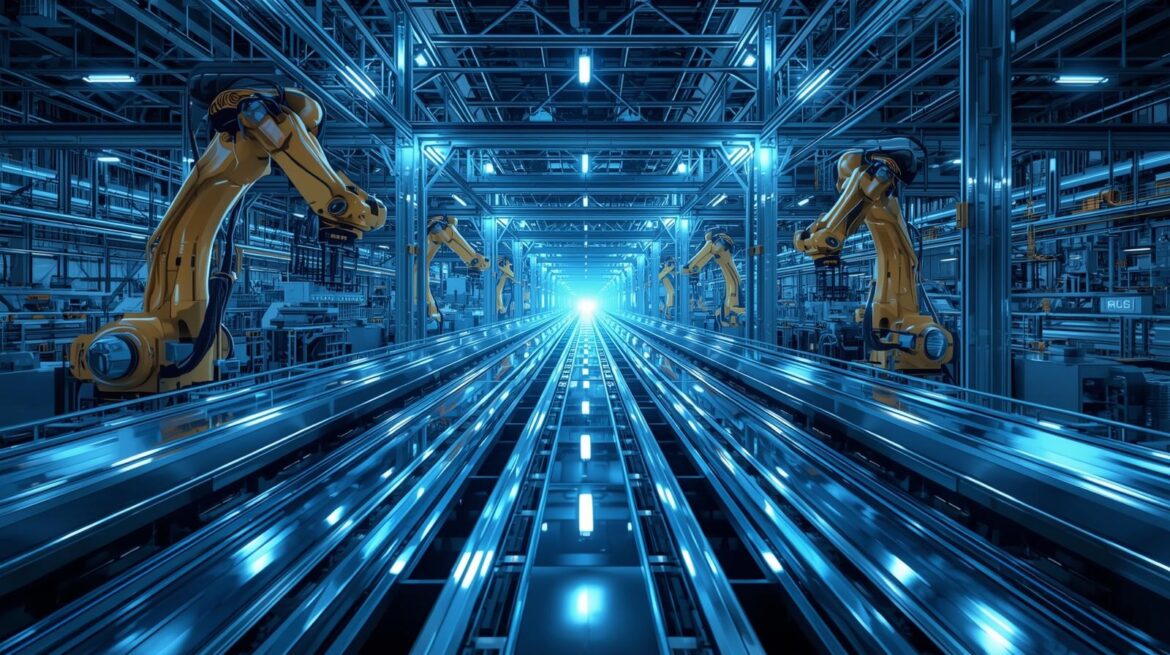

Robotics and Collaboration Between Humans and Machines

Industrial robots continue to proliferate. Modern factories already house millions of robotic units, a figure that is steadily rising as costs decline and capabilities improve. In the automotive, electronics, and metalworking sectors, robots increase throughput and carry out repetitive or hazardous tasks, freeing human workers for more creative and supervisory roles.

A particularly impactful trend is the rise of collaborative robots or “cobots”. Unlike traditional industrial robots that operate in cages, cobots work safely alongside humans. This democratizes automation — even small and mid-sized enterprises can benefit from increased productivity while preserving jobs.

However, the transition won’t be without challenges. Some roles will evolve or vanish, requiring upskilling and new education pathways for workers to remain relevant. Nevertheless, most experts agree that automation will augment human labor rather than replace it entirely – increasing job satisfaction and safety in many fields.

Edge Computing & 5G Connectivity

Future factories will depend on lightning-fast communication networks to process data at the source – a concept known as edge computing. Combined with 5G connectivity, this enables ultra-low latency, meaning machines can respond in real time to changing conditions without delays.

Edge computing also improves system reliability. Instead of sending all data to a central server or cloud, critical analytics happen locally, making automation systems more resilient to network disruptions. This capability is especially important for sectors like automotive manufacturing, where split-second decisions can impact safety and product quality.

Sustainability and Energy Efficiency

Automation is no longer solely about speed and cost reduction – it’s increasingly linked to sustainability. Smart systems can balance production with energy usage, cutting waste and costly emissions. For example, IIoT systems can track energy consumption at the machine level, leading to optimized power usage and lower carbon footprints.

The shift toward green manufacturing aligns with global environmental goals and regulatory pressures. Factories that fail to improve sustainability risk falling behind competitors in markets that increasingly favor environmentally responsible products.

Challenges Ahead

Despite promising advancements, several hurdles remain.

Skills gap: Many manufacturers face a shortage of engineers and technicians trained in AI, robotics, and IIoT integration. This gap risks slowing automation projects and could leave companies vulnerable to cyber threats.

Integration difficulties: Older factories must retrofit legacy systems, which is often costly and complex. Seamless interoperability between new and existing infrastructure remains a significant barrier.

Cost and adoption: High initial costs for automation technology can be prohibitive for small and medium-sized enterprises (SMEs), slowing broader adoption across industries.

However, these challenges are not insurmountable. Industry partnerships, government incentives, and targeted training programs can help bridge these gaps, making automation more accessible and secure.

Conclusion: The Road to 2030

By 2030, industrial automation will be shaped by connectivity, intelligence, human-machine collaboration, and sustainability. While obstacles exist – particularly around workforce readiness and integration costs – the overall trajectory is positive. Manufacturers that embrace digital transformation now will reap rewards in efficiency, quality, and competitiveness, while also creating safer, more engaging work environments.

In short, the future of manufacturing is not only automated but also smart, sustainable, and human-centric.

References / Sources

- Trends in Industrial Automation – Autodesk (2025) Trends in Industrial Automation by 2030

- 13 Trends That Will Define Future Manufacturing – StartUs Insights Future of Manufacturing 2025–2030

- Smart Manufacturing Growth Forecast – Manufacturing Today India Smart Manufacturing to $600B by 2030

- IoT and Edge Computing in Manufacturing – Markets and Markets IoT & Edge Computing in Manufacturing 2030

- The Future of Industrial Automation – MachTech News Analysis Industrial Automation Trends & Challenges

- Industrial Robot Adoption Data – Times.CBA Manufacturing Automation & Robot Density