In 2025, robotics is no longer just about precision and repetition — it’s about adaptability, intelligence, and collaboration. The manufacturing world has entered a new phase where robots are evolving into smart, flexible co-workers, capable of adjusting to real-time changes on the factory floor.

A New Era of Human-Robot Collaboration

The days of robots locked in cages are behind us. Today’s factories are embracing collaborative robots, or cobots, which are designed to work side-by-side with human workers. Unlike traditional robots that required strict safety zones, cobots are lightweight, easy to program, and equipped with advanced safety features like force sensors and AI motion prediction.

What’s driving this shift is the demand for agile production environments. Companies want to automate without the massive infrastructure changes that used to be required. Cobots are ideal for small-batch and high-mix manufacturing, as they can be quickly reconfigured and deployed. This has made them especially popular in industries like electronics, medical devices, and consumer goods.

Vision Systems and Artificial Intelligence

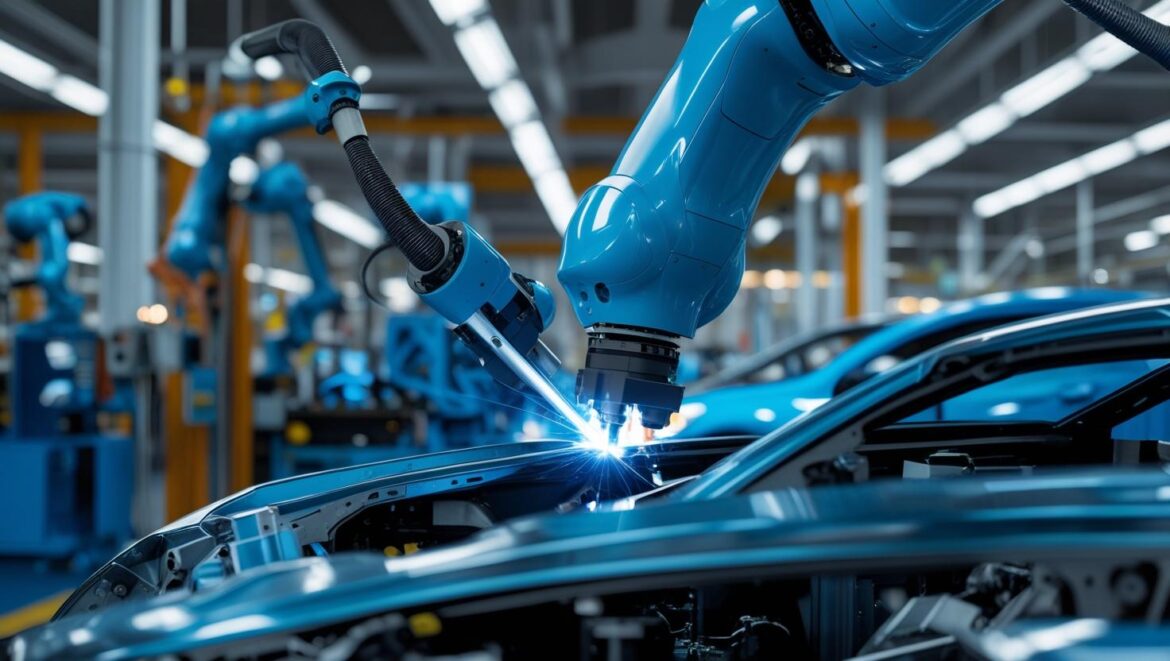

One of the biggest enablers of smart robotics is the advancement in machine vision and AI algorithms. Modern robots are equipped with cameras, LiDAR, and 3D sensors that allow them to perceive and interpret their surroundings — in real-time. With the help of deep learning, robots can now identify complex patterns, detect defects, and make decisions on the fly.

This combination of AI and vision is improving quality control across industries. In the automotive sector, for example, robotic systems can spot imperfections that are invisible to the human eye. In packaging and logistics, robots are sorting irregular items with impressive speed and accuracy. These systems also learn over time, constantly refining their performance with each task they complete.

From Fixed Lines to Mobile Autonomy

The factory of 2025 is no longer static. Instead of being tied to fixed conveyors or guided tracks, many manufacturers are turning to Autonomous Mobile Robots (AMRs). These machines use SLAM (Simultaneous Localization and Mapping) technology to move freely within a space, avoiding obstacles, and dynamically planning paths.

AMRs are revolutionizing intralogistics, reducing the need for forklifts and human-operated carts. They can transport materials between workstations, restock inventory, or deliver parts to assembly lines — all without supervision. This level of autonomy boosts efficiency and reduces downtime, especially in large-scale operations with multiple production areas.

Robotics-as-a-Service: Lowering the Barrier to Entry

One of the most exciting business model shifts in robotics is the rise of Robotics-as-a-Service (RaaS). Instead of purchasing expensive equipment outright, manufacturers can now subscribe to robotics solutions on a monthly basis — complete with software, maintenance, and performance guarantees.

This model is proving especially useful for small and mid-sized enterprises (SMEs), who often struggle to afford traditional automation systems. With RaaS, these companies gain access to cutting-edge robotics without long-term financial risks. Providers like Formic, Ready Robotics, and Dexterity are already disrupting the market with scalable and customizable automation platforms.

Safety and Ethics in the Age of Intelligent Machines

As robots become smarter and more autonomous, safety standards and ethical concerns are also evolving. Updates to ISO 10218 and ISO/TS 15066 reflect the growing need to address AI-driven decision-making, human proximity sensing, and ethical deployment.

Factories are now implementing predictive safety systems, using AI to anticipate collisions or unsafe movements before they occur. Meanwhile, organizations are beginning to develop ethical AI frameworks, ensuring robots are used to assist workers rather than replace them indiscriminately.

This ethical approach is not only good for workplace culture — it’s also proving essential for long-term sustainability. Companies that focus on human-robot collaboration are seeing higher employee satisfaction, faster adoption of automation, and greater innovation overall.

The Future Is Flexible, Intelligent, and Human-Centric

Looking ahead, robotics in industrial automation will continue to evolve toward greater flexibility, intelligence, and accessibility. Whether it’s cobots working shoulder-to-shoulder with technicians, mobile robots streamlining logistics, or AI-powered systems improving quality control — the technologies driving 2025 are deeply transforming the way we produce, move, and innovate.

Industrial automation is no longer reserved for large corporations or high-volume production lines. Thanks to modular systems, cloud connectivity, and service-based models, automation is more inclusive than ever before — empowering even the smallest manufacturers to compete globally.

As we continue through the decade, one thing is clear: robots aren’t taking over — they’re teaming up.

Sources

- IFR – World Robotics Report 2025

- Universal Robots Case Studies

- MiR – Mobile Industrial Robots

- Formic – RaaS for Manufacturers

- ISO Robotics Safety Standards